-

Precision Sheet Metal Fabrication

-

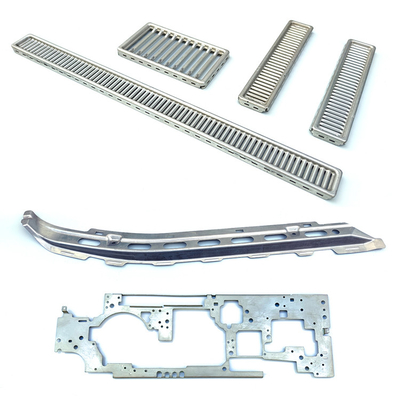

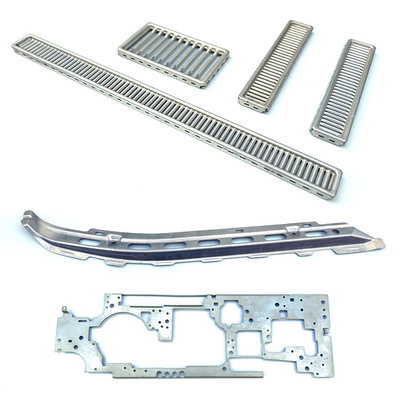

Stainless Steel Sheet Metal Fabrication

-

Sheet Metal Stamping

-

Automotive Sheet Metal Components

-

Medical Equipment Parts

-

Sheet Metal Assembly

-

Plastic Injection Molding

-

Sheet Metal Forming

-

Sheet Metal Welding

-

Metal Laser Cutting

-

Sheet Metal Bending

-

Sheet Metal Powder Coating

-

Custom Metal Fabrication

-

Custom Plastic Molding

-

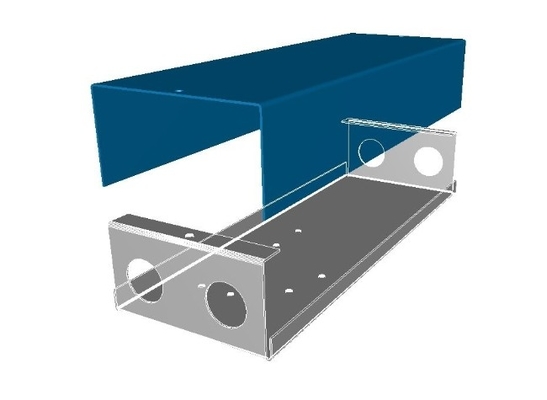

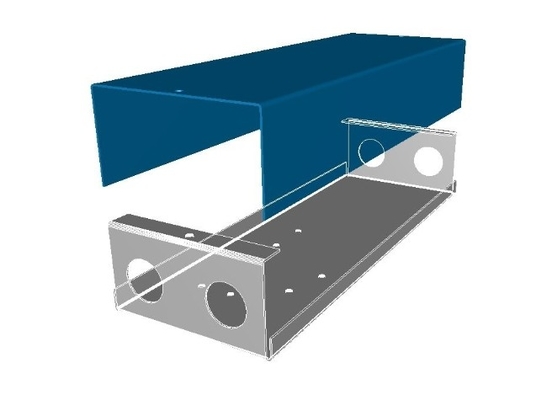

Customized Metal Bracket

-

Custom Metal Enclosures

-

Windmill Parts

Auto Sheet Metal Fabrication Welding Aluminum Metal Tile Trim

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum, Carbon Steel, Stainless Steel, SPCC, Cold Roll Steel | Application | Industry, Electronic Parts, Used Widely In Auto, Construction, Furniture |

|---|---|---|---|

| Process | Welding, Stamping, Laser Cutting, CNC Punching, Punching Or Deep Drawing | Service | OEM ODM, Customized OEM, OEM Service |

| Type | Stamping Parts, Sheet Metal, Sheet Metal Stamping Tensile Forming Clamps, Manufacturer | Tolerance | +/- 0.05mm Or As Per Customer Drawing, +/-0.1~0.05mm, As Per Specification |

| Thickness | Depends On Your Products, 0.08mm-45mm | Product Name | Black Gold Rose Gold Polished Square Round Shape Stainless Steel Metal Tile Trim |

| Finish | Thermosetting Powder Coating, Customer Request, Baked Blue, Painted, Polishing Etc. | Experience | 19 Years+ |

| Provide | OEM Service | Specification | Customized According To Your Drawings |

| Highlight | Aluminum sheet metal fabrication welding,Stainless Steel Metal Tile Trim,auto sheet metal fabrication welding |

||

| Service | OEM ODM, Customized OEM, OEM service | |

|---|---|---|

| Surface treatment | Powder coating, Polishing, Galvanized, Nickle plated, Anodizing |

Black Gold Rose Gold Polished Square Round Shape Stainless Steel Metal Tile Trim

1 Sheet metal bending?

Hot rolled steel plate. The above materials need to be operated by different bending processes due to

their material properties. Hot rolled steel plate is the most afraid of bending material, is also the most

difficult to fold material. Hot rolled steel, also known as SPHC, develops a hard layer of ferric tetroxide

on its surface as it is rolled. The mechanical properties of the internal material elongation is not very

good, in the bending process is easy to crack.

2 Technical Parameters

| Product name | Black Gold Rose Gold Polished Square Round Shape Stainless Steel Metal Tile Trim |

| Item | Mig Welding 20 Gauge Sheet Metal Welding Corrugated Metal Sheet Metal Welding |

| Provide | OEM |

| Specification | Customized According to your drawings |

| Material | stainless steel, SPCC, Cold roll steel |

| Application | electronic parts, Used widely in auto, construction, furniture |

| Process | Stamping, Laser cutting, CNC Punching, punching or deep drawing |

3 Product Details

Use: Car

Function: structure part of the car door, is a Z shape connected part.

Technology: metal stamping, punch press, bending

4 About Strong

![]()

![]()

Strong focused on metal manufacturing and has comprehensive ability in mold self-design, metal

stamping, sheet metal, laser cutting, powder coating, welding, plastic injection, etc.

Strong has many advanced production equipments: 50+ punch press machines (highest 1000 ton),

20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic

welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,

etc. In terms of the QC testing tool, We have CMM, a two-dimensional measuring instrument, hardness

tester, salty frog tester, etc.

Strong metal was established in June 2003 with a total registered capital of 67 million yuan and a total

construction area of 30,000 square meters. It has 5 factories in total which are located in Nantong,

Taicang, Nanjing, Vietnam, and Shanghai.

In 2021, the yearly turnover of Strong has exceeded 200 million yuan and we keep going to search

and offer better solutions to our customers and make more value to create a better world.

5 FAQ

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock,

it is according to quantity.

Q: Are you a trading company or manufacturer?

A: We are a manufactory.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance

before shipment.

If you have another question, pls feel free to contact us.