-

Precision Sheet Metal Fabrication

-

Stainless Steel Sheet Metal Fabrication

-

Sheet Metal Stamping

-

Automotive Sheet Metal Components

-

Medical Equipment Parts

-

Sheet Metal Assembly

-

Plastic Injection Molding

-

Sheet Metal Forming

-

Sheet Metal Welding

-

Metal Laser Cutting

-

Sheet Metal Bending

-

Sheet Metal Powder Coating

-

Custom Metal Fabrication

-

Custom Plastic Molding

-

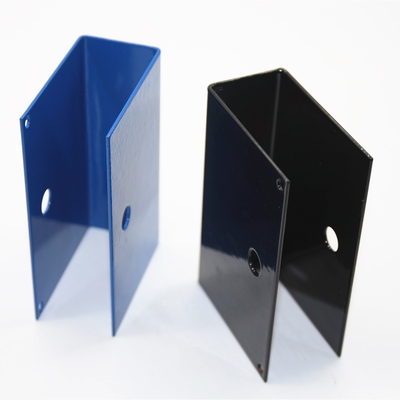

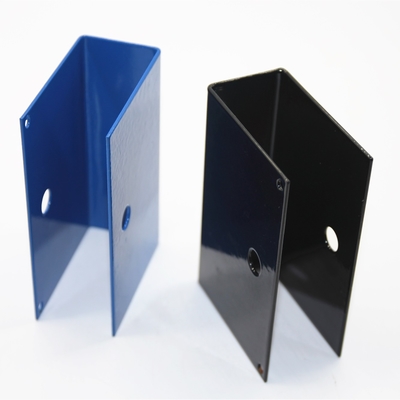

Customized Metal Bracket

-

Custom Metal Enclosures

-

Windmill Parts

Precision Sheet Metal Fabrication Custom Oem Stamping Processing Metal Parts

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum, Stainless Steel, SPCC, Brass, Copper | Surface Treatment | Powder Coating, Available, Polishing, Painting, Wire Drawing |

|---|---|---|---|

| Equipment | Stamping Machine, Welding Machine, Deep Drawn Machines, Laser Cutter | Size | Standard Customize |

| Service | OEM Customized | Place Of Origin | China,Shanghai |

| Color | White Black Blue Purple Yellow Gray Orange Green , Normally Customized, Negotiatable | Order Online | Supported |

| Cooperation Mode | OEM/ ODM, Manufacture According To The Drawings That Customer Offerd | Process | Bending, Stamping, Metal Cutting, Precision Metal Stamping, Stamping/Bending/Punching/Welding Etc. |

| Place of Origin | China | |

|---|---|---|

| Color | Customized | |

| Certificates | ISO 14001 ISO45001 EN15085 IATF 16949 ISO 3834 | |

| Product name | Precision Sheet Metal Fabrication Custom Oem Stamping Processing Metal Parts |

Precision Sheet Metal Fabrication Custom Oem Stamping Processing Metal Parts

1 Identification:

Sheet metal is sometimes used as lever metal. This word comes from English Platemetal. It is generally

used to make some metal sheet produce plastic deformation by manual or die stamping to form the desired

shape and size, and can further form more complex parts by welding or a small amount of mechanical

processing.

Common objects -- such as chimneys, iron stoves, and car casings -- are sheet metal pieces.

"Sheet metal processing" refers to any thick metal that can be molded into plates of various thicknesses.

Metals in the sheet metal industry include cold-rolled steel, mild steel, stainless steel, tin, nickel,

Titanium, aluminum, brass, and copper. Using specialized tools, sheet metal workers cut, roll, bend, and

Shaping these metal plates allows unlimited bending pressures over 110 tons of back pressure and stamping

Settings.

Strong focused on metal manufacturing and has comprehensive ability in mold self-design, metal

stamping, sheet metal, laser cutting, powder coating, welding, plastic injection, etc.

2 Technical Parameters

| Product name | Aluminium Laser Cutting Service Precision Metal Manufacturing Sheet Metal Fabrication |

| Key Words | Aluminium Sheet Metal Fabrication Sheet Metal Ductwork Fabrication Precision Metal Fabrication |

| Application | Industry, |

| Process | Bending |

| Cooperation mode | Customized OEM, OEM/ODM, OEM ODM Metal Stamping, Design+Drawing+Processing+OEM, Manufacturer |

| Material | Stainless steel, |

3 Product Details

Use: Train seat

Function: assembled in the bottom of the seat and for turning the seat in a different direction

Technology: laser cutting, welding, powder coating

![]()

![]()

![]()

4 About Strong

![]()

The company has more than 300 employees, and more than 40 engineers, including engineering engineers,

drawing engineers and so engineers, quality engineers, and process engineers. We can provide services from

drawing to drawing Samples and bulk, 24 hours technical support.

Strong metal was established in June 2003 with a total registered capital of 67 million yuan and a total

construction area of 30,000 square meters. It has 5 factories in total which are located in Nantong,

Taicang, Nanjing, Vietnam, and Shanghai.

In 2021, the yearly turnover of Strong had exceeded 200 million yuan and we keep going to search

and offer better solutions to our customers and make more value to create a better world.

Strong focused on metal manufacturing and has comprehensive ability in mold self-design, metal

stamping, sheet metal, laser cutting, powder coating, welding, plastic injection, etc.

Strong has many advanced production equipments: 50+ punch press machines (highest 1000 ton),

20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic

welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,

etc. In terms of the QC testing tool, We have CMM, a two-dimensional measuring instrument, hardness

tester, salty frog tester, etc.

Our factory's main products are OEM and ODM metal and plastic manufacturing services.

We could customize products according to the 2D/3D drawings from customers. We could offer laser

cutting, bending, welding, powder coating, milling, molding, machining, plastic injection, and so on.

Strong focus on lean production and we aim to try out best to be more efficient, time saved, and cost

saved.

![]()

5 FAQ

Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance

before shipment.

If you have another question, pls feel free to contact us.