-

Precision Sheet Metal Fabrication

-

Stainless Steel Sheet Metal Fabrication

-

Sheet Metal Stamping

-

Automotive Sheet Metal Components

-

Medical Equipment Parts

-

Sheet Metal Assembly

-

Plastic Injection Molding

-

Sheet Metal Forming

-

Sheet Metal Welding

-

Metal Laser Cutting

-

Sheet Metal Bending

-

Sheet Metal Powder Coating

-

Custom Metal Fabrication

-

Custom Plastic Molding

-

Customized Metal Bracket

-

Custom Metal Enclosures

-

Windmill Parts

Home Appliance Components Custom Metal Stamping Services Fabrication Part

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Stainless Steel, Aluminum, Carbon Steel, SPTE, SECC | Application | Industry, Metal Parts, Home Appliance, Auto /medical/agricultural/train/valve/textile, Ductwork |

|---|---|---|---|

| Process | Bending, Stamping, Metal Cutting, Precision Metal Stamping, Stamping/Bending/Punching/Welding Etc. | Color | All Color Is Available |

| Order Online | Provided | Type | Stamping Hardware Part |

| Item | OEM Stamping Parts, Sheet Metal Fabrication, Metal Stamping, 76 | Sample Comfirm | Free |

| After Sale Service | Online After-sales Service | Product Name | Custom Components Processing Stamping Products Fabrication Part Sheet Metal Manufacture |

| Highlight | custom metal stamping services ISO,OEM stamping manufacturing process,home appliance custom metal stamping services |

||

| Material | Stainless steel, Aluminum, Carbon steel, SPTE, SECC |

|---|

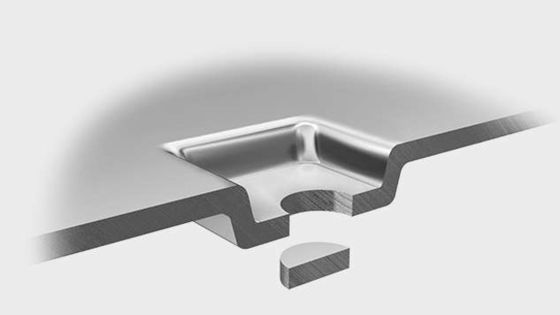

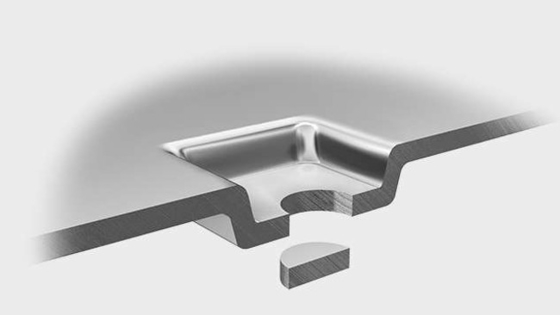

Custom Components Processing Stamping Products Fabrication Part Sheet Metal Manufacture

1 Laser drilling technology

Laser drilling technology is the earliest practical laser technology in laser material processing technology. Laser drilling

in sheet metal workshop is generally used pulse laser, high energy density, short time, can be processed 1μm hole, especially

suitable for processing with a certain Angle and thin material hole, but also suitable for processing high strength hardness

or brittle soft material parts of the deep hole and small hole.

2 Technical Parameters

| Product name | Custom Components Processing Stamping Products Fabrication Part Sheet Metal Manufacture |

| Name | Deep Drawn Metal Stampings Stainless Steel Sheet Metal Welding Sheet Metal Stamping Bending Fabrication |

| Type | Customized Stamping Hardware Part, sheet metal |

| Color | OEM Aluminum Alloys, |

| Item | Customized stamping parts, sheet metal fabrication, Metal Stamping, 76 |

| Tolerance | 0.003~0.01mm, Customized |

| Mould fee | free |

| Clor | All color is available |

| After sale service | Offer best service |

3 Product Details

Use: Car

Function: structure part of a car door, use it to conect different metal parts.

Technology: metal stamping, punch press, powder coating

4 About Strong

![]()

![]()

Strong has many advanced production equipments: 50+ punch press machines (highest 1000 ton),

20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic

welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,

etc. In terms of the QC testing tool,

Strong metal was established in June 2003 with a total registered capital of 67 million yuan and a total

construction area of 30,000 square meters. It has 5 factories in total which are located in Nantong,

Taicang, Nanjing, Vietnam, and Shanghai.

5 FAQ

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock,

it is according to quantity.

Q: Are you a trading company or manufacturer?

A: We are a manufactory.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance

before shipment.

If you have another question, pls feel free to contact us.