-

Precision Sheet Metal Fabrication

-

Stainless Steel Sheet Metal Fabrication

-

Sheet Metal Stamping

-

Automotive Sheet Metal Components

-

Medical Equipment Parts

-

Sheet Metal Assembly

-

Plastic Injection Molding

-

Sheet Metal Forming

-

Sheet Metal Welding

-

Metal Laser Cutting

-

Sheet Metal Bending

-

Sheet Metal Powder Coating

-

Custom Metal Fabrication

-

Custom Plastic Molding

-

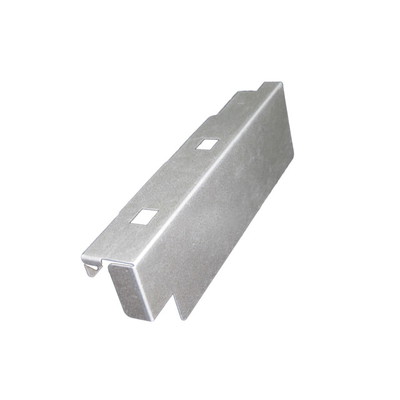

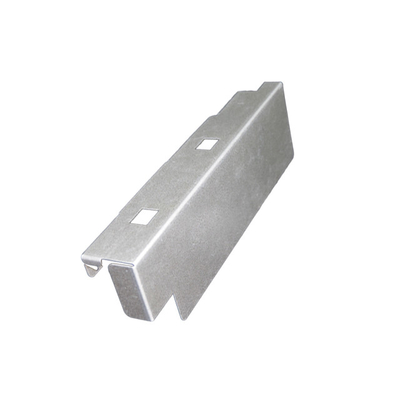

Customized Metal Bracket

-

Custom Metal Enclosures

-

Windmill Parts

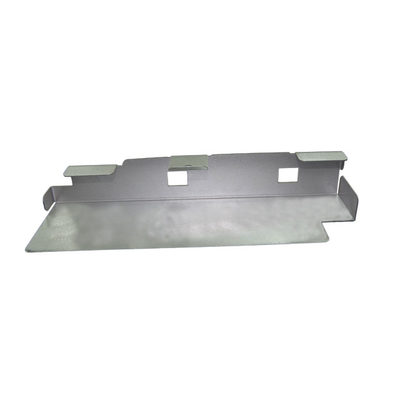

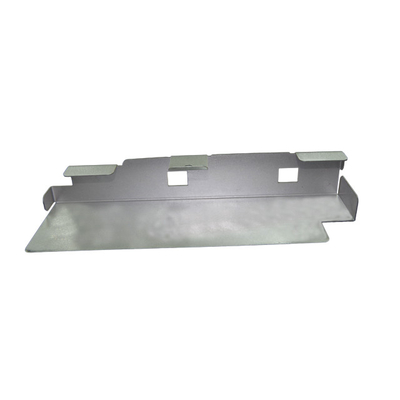

Wall hanging furnace control box guard plate Stainless Steel Precision Service

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Household Appliance, Various Range | Equipment | Stamping Machine, Welding Machine, Deep Drawn Machines, Laser Cutter |

|---|---|---|---|

| After-sales Service Provided | Online | Experience | 19 Years+ |

| Mould Fee | Free | Sample Comfirm | Free Sample |

| Material | Carbon Steel, Stainless Steel, Brass, Copper, Aluminium | Application Case | Industrial, Building Material, Auto, All Fields, Machine Parts |

| Highlight | precision stainless steel,precision metal fabrication |

||

| Place of Origin | China | |

|---|---|---|

| Brand | Strong | |

| Order Online | Supported | |

| Cooperation mode | OEM/ ODM, manufacture according to the drawings that customer offerd |

Manufacture Custom Stainless Steel Aluminum Sheet Metal Fabrication

1 Application of electrostatic spraying in sheet metal processing

Laser in each contact with new equipment, or a new experiment, the first step must be focusing, only to

find their own focal plane, in order to correctly determine the other process parameters such as defocus,

power, speed, etc., do know.

2 Technical Parameters

| Product name | Wall hanging furnace control box guard plate Stainless Steel Precision Service |

| Key Words | Sheet Metal Project Sheet Metal service |

| Place of Origin | China |

| Brand | Strong |

| Material | DX51D+Z, |

| Color | Yellow |

3 Product Details

Use: Train seatFunctions: Assembled at the bottom of the seat to turn the seat in different directions

Technology: laser cutting, welding, powder spraying

4 About Strong

![]()

The dot method is also divided into a variety of, each manufacturer will have different use habits: suitable for

larger focal depth, spot size change in the direction of the Z axis of the fiber laser, through a row of points,

see the changing trend of the plate surface point, adjust the Z axis change 0.5 mm each time, and mark on the

steel plate from large to small, and then from small to large process, the smallest point is the focus.

![]()

5 FAQ

Q: Are you a trading company or manufacturer?

A: We are a manufactory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance

before shipment.

If you have another question, pls feel free to contact us.